It is a long established fact that a reader will be distracted by the readable content of a page when looking at its layout. The point of using Lorem Ipsum is that it has a more-or-less normal distribution of letters, as opposed to using 'Content here, content here', making it look like readable English. Many desktop publishing packages and web page editors now use Lorem Ipsum as their default model text, and a search for 'lorem ipsum' will uncover many web sites still in their infancy. Various versions have evolved over the years, sometimes by accident, sometimes on purpose

YSH KALIP VIDEO

In our company, plastic and aluminum injection tools and parts are produced.

OUR CLIENTS

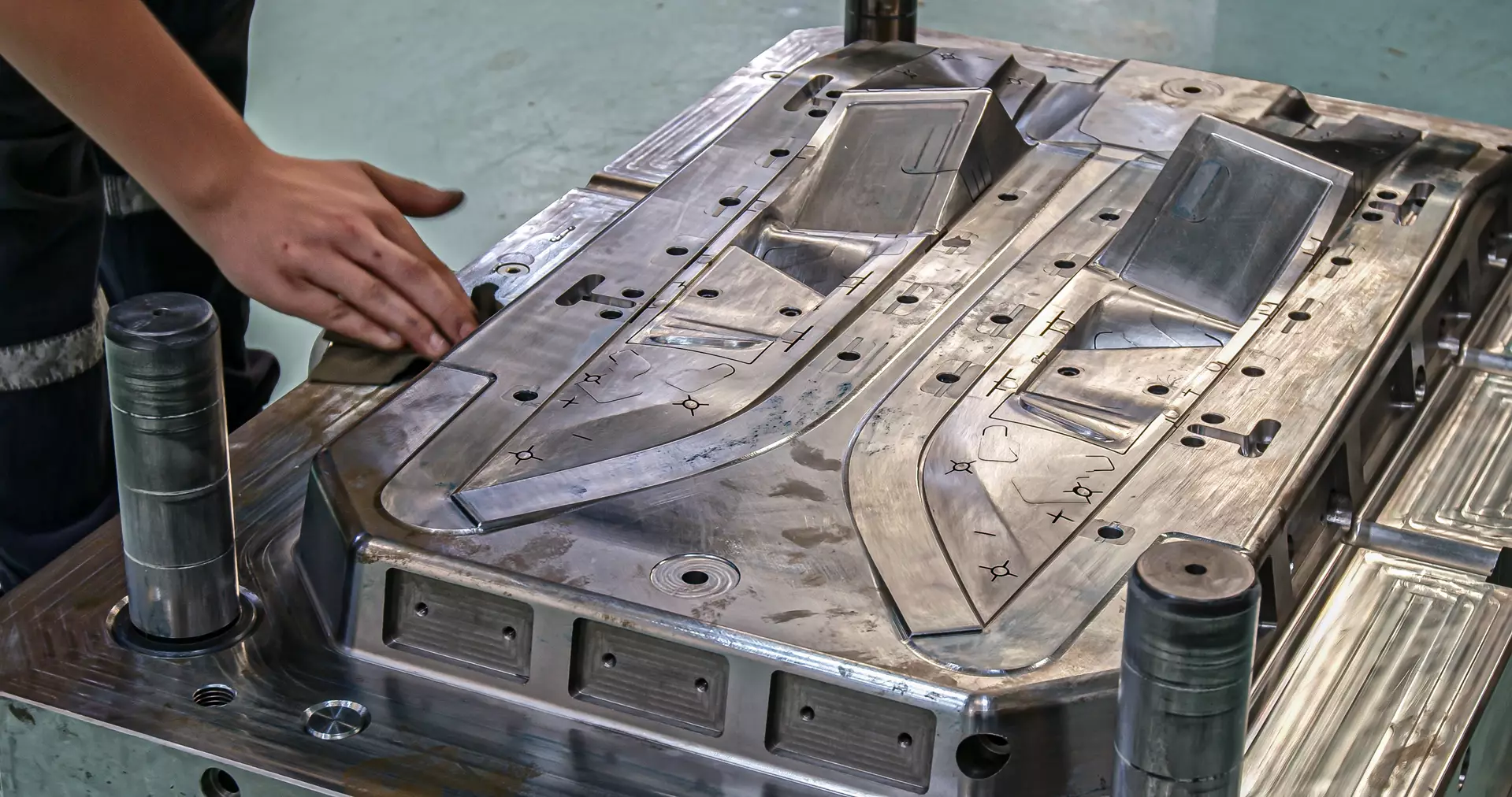

TOOLSHOP

Our tooling department is equipped with the latest technology CNC machines, including top brands such as Hermle and Deckel Maho, ensuring precision and efficiency in every step. All processes are carried out in-house by our highly experienced and skilled team, allowing us to maintain full control over quality and timelines. With a wide range of state-of-the-art machinery, we are recognized and chosen by our customers for our reliability and expertise. Our extensive machine park provides us with the capability to meet diverse and complex tooling demands with the highest standards of excellence.

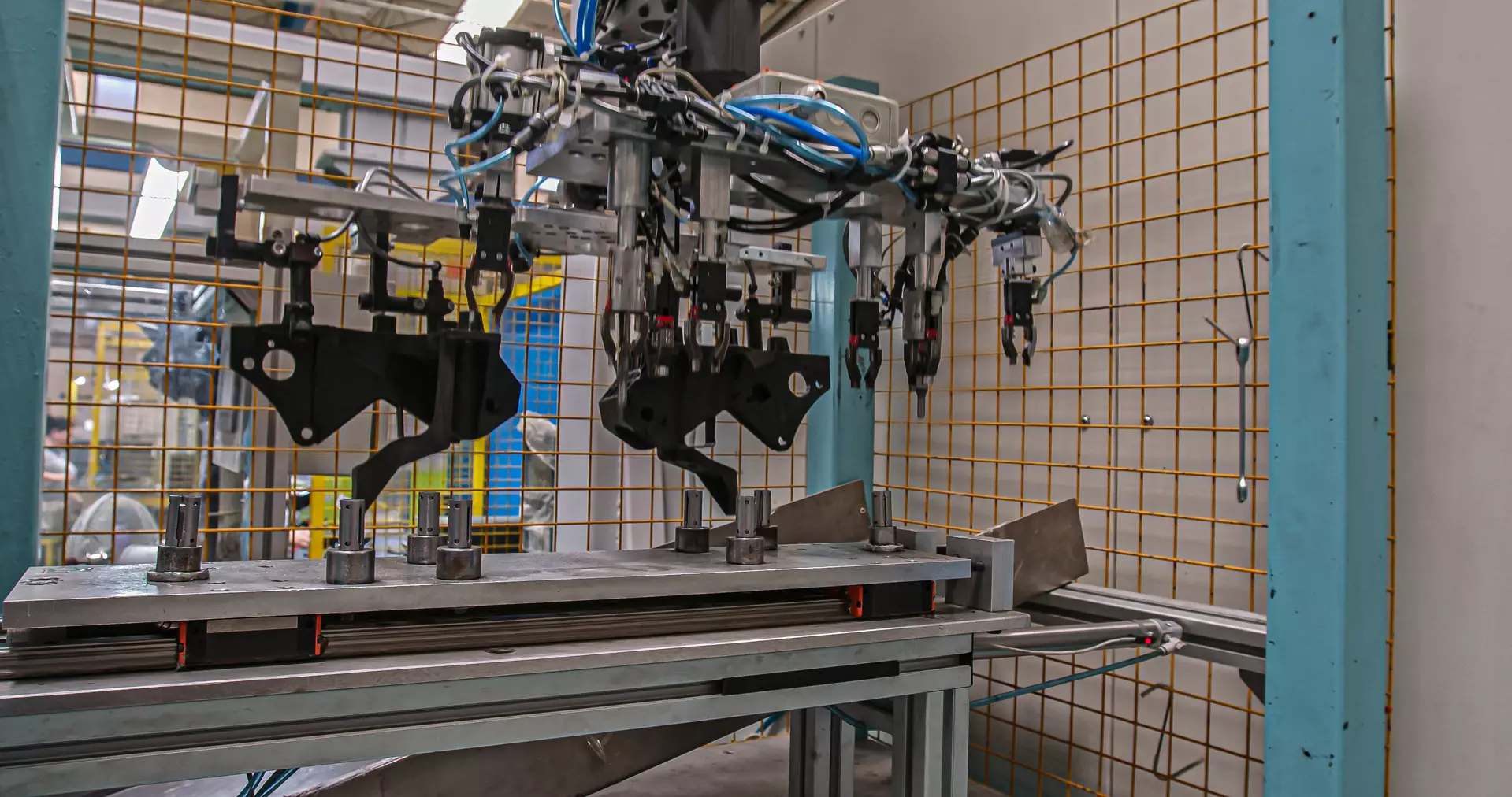

PLASTIC INJECTİON

YSH Koç Kalıp is a leading company with over 30 years of experience specializing in plastic injection and assembly solutions for the automotive industry. Our 17 injection moulding machines (13 Krauss Maffei, 4 Engel), ranging from 80 tons to 650 tons, are integrated with advanced automation robot systems to deliver high precision and efficiency. Operating with a 3-shift system, our production line runs continuously, and our integrated parts assembly line allows us to provide assembled products to our customers. With our expert team, high-quality raw materials, and modern technological infrastructure, we always aim to maintain the highest level of customer satisfaction.

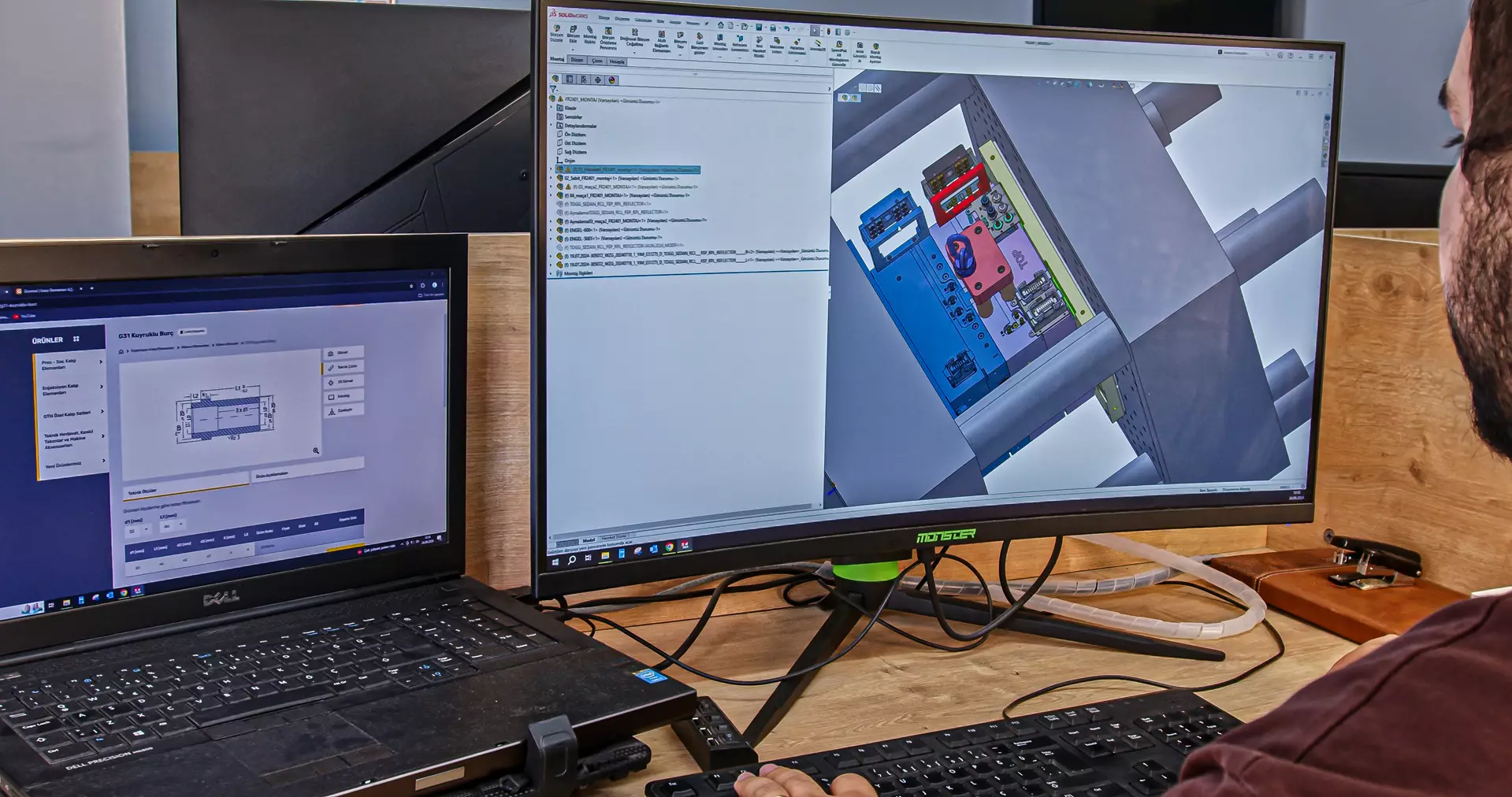

R&D

Our R&D department aims to provide the best solutions to our customers by utilizing latest-technology software and analysis tools. We optimize injection processes with Moldflow analysis and support our projects through advanced CAD and CAM programs such as HYPERMILL, SOLIDWORKS, SIEMENS NX, and MASTERCAM, ensuring high precision and efficiency. Additionally, we ensure quality control with our ATOS Q PRO machine, which offers top-level measurement accuracy. Our R&D team consists of highly skilled and experienced professionals who continuously follow the latest technological advancements and are committed to self-improvement.